- #FREE SIMPLE PLYWOOD CUTTING OPTIMIZER HOW TO#

- #FREE SIMPLE PLYWOOD CUTTING OPTIMIZER SKIN#

- #FREE SIMPLE PLYWOOD CUTTING OPTIMIZER FREE#

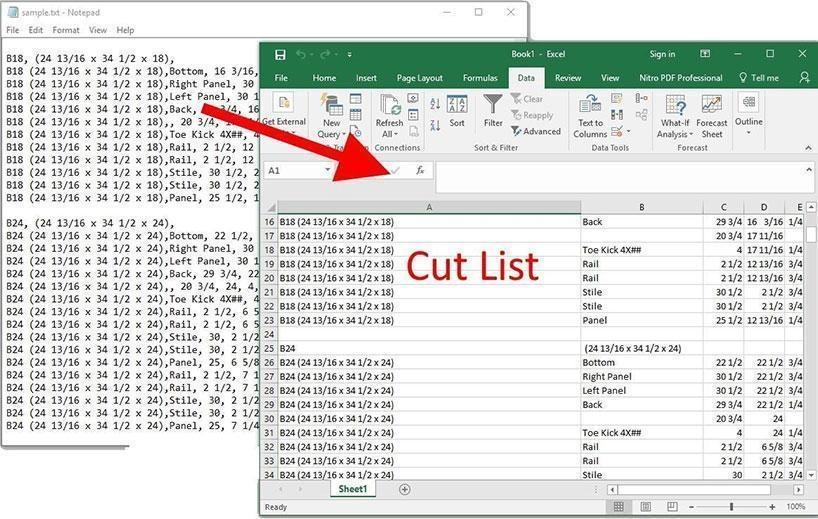

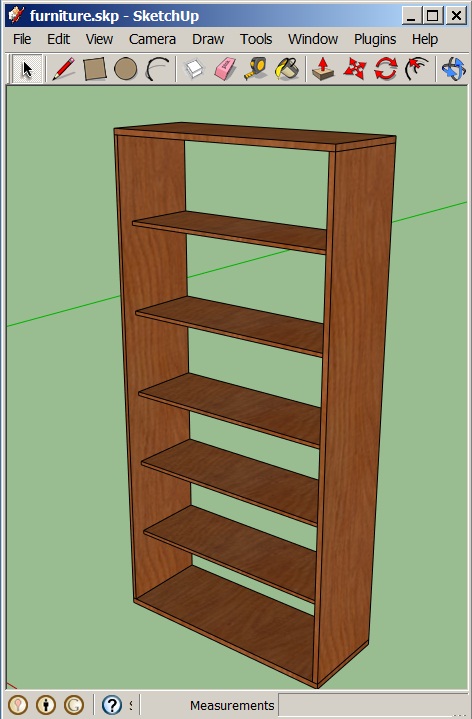

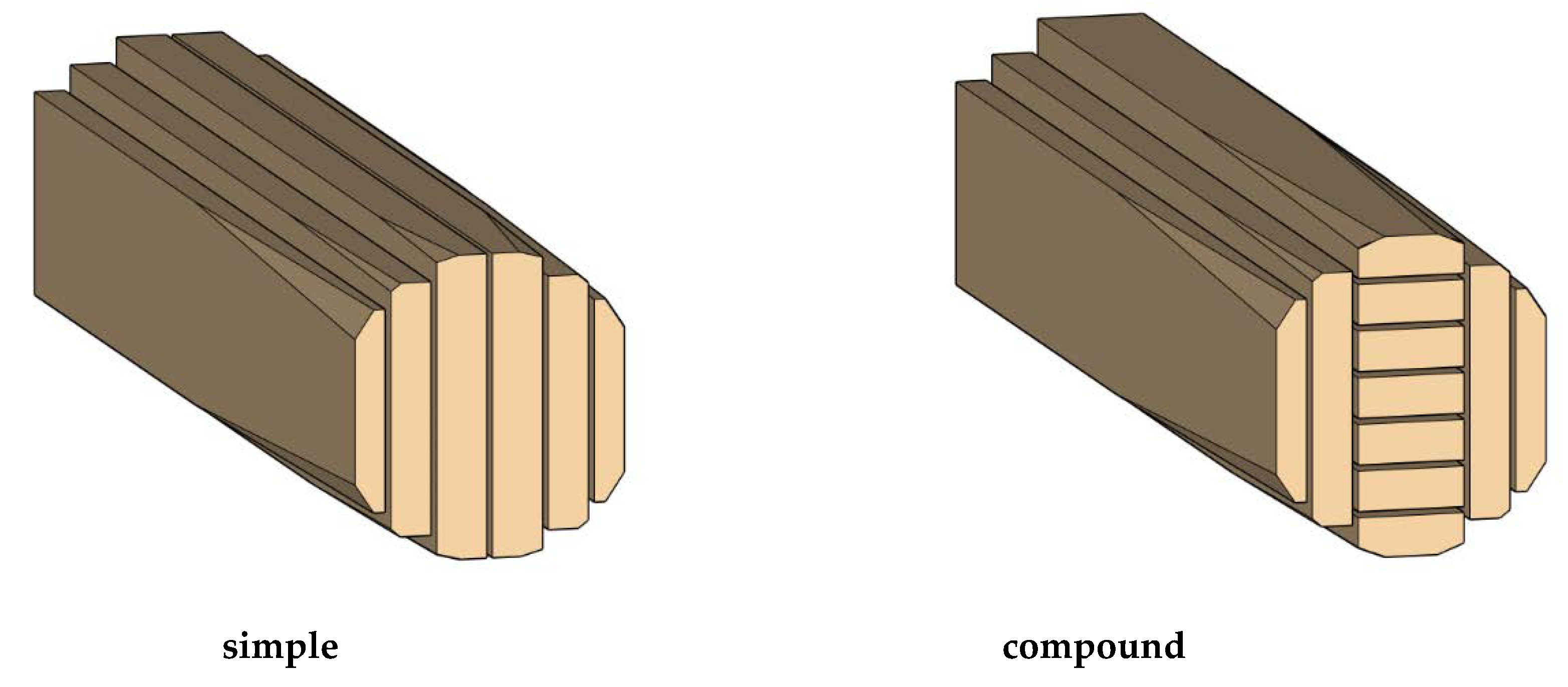

Use a side table if needed to help support large workpieces.Um den Solver nutzen zu können, muß man ihn zunächst mal aktivieren. Now rotate the workpiece clockwise into cross grain first (so the blade doesn't pull into long grain) to cut out a circle. Push the jig forward on the saw table until it stops, and clamp it in place. To use the jig, drill a small hole on the bottom of the workpiece at its center and place it over the finish nail installed in the jig. Draw a line across the jig that's perpendicular to the blade and even with the tips of the teeth - here's where you'll insert a finish nail pivot. Then attach a block underneath to stop the jig here. Place the cleat in the miter slot and push the jig into the spinning blade until the base's back edge is flush with the table edge. If you need a quick, simple circle jig, start with a 3/4" plywood base roughly the size of the band saw table with a miter slot cleat glued to the bottom. The workpiece turns on a pivot pin, and rotating it into the saw blade cuts a circle. Mark circle radii on this line.Ĭutting out circles on a band saw with a jig works on the same principle as the disc sander method. On the band saw jig, draw a line perpendicular to the blade. I have also found that positioning the workpiece and jig closer to the center of the sanding disc, where it spins more slowly, helps reduce endgrain burning. I clean mine periodically with a crepe block. To avoid excessive burns on the edges, rotate the workpiece steadily and use a clean sanding disc. The clamped runner and a finish nail establish the circle's radius. Use the jig to cut circles on your sander by rotating the workpiece clockwise. Reset the runner forward and sand the edges of the circle in the same manner until you reach the desired circle diameter. Sand the workpiece by slowly rotating it clockwise until a circle is formed.

Push the runner forward until the workpiece contacts the spinning sanding disk, then clamp the runner in place. Drill a small hole in the center of the bottom face of the workpiece and fit the workpiece over the finish nail. To cut a circle, clamp the jig to the table of the disc sander with the cleat in the miter slot. You can see my completed jig in the photo. To complete the jig, insert a finish nail near one end of the runner.

Cut a dado on the top surface perpendicular to the underside cleat, and fit a runner into the dado. Position and glue a cleat to the bottom face of the plywood base such that when the cleat is in the miter slot, it positions the base about 1/16" from the sanding disc. Start with a piece of 1/2" or 3/4" plywood that's a little bigger than the table of the disc sander. The sanding circle jig I have is relatively simple. With the aid of a jig, your disc sander can be turned into a circle-making tool. The jig for a disc sander has an adjustable runner on top. Retract the hole saw often to reduce friction and help clear the sawdust. Second, the key to cutting a burn-free disc is to start with a sharp hole saw and don't force the saw into the wood. Apart from the backer board, I have two other drilling tips to share.įirst, did you know that you can double the cutting depth of a hole saw? Here's how: Start drilling with the hole saw on one side of the workpiece and, once the pilot bit has poked through, flip the wood over and continue cutting using the same pilot hole. What has to be the world's simplest way to make small circles (from 3/4" up to 7" diameter) is to use a hole saw and a backer board (to prevent blowout). When creating circles with a hole saw, make sure to drill with light pressure and retract it often to clear trapped sawdust.

So if you've ever been challenged by circle cutting, here are some tool options to try. I'll also share tricks for cutting circles without leaving any pivot holes on the finished piece.

#FREE SIMPLE PLYWOOD CUTTING OPTIMIZER HOW TO#

I'll show you both how they work and how to get the best results from each technique. In this article, I have selected six methods from my bag of tricks.

#FREE SIMPLE PLYWOOD CUTTING OPTIMIZER SKIN#

I don't know how many ways there are to skin a cat (my apologies to all cat lovers), but I do know, and use, more than half a dozen different ways to cut circles.

#FREE SIMPLE PLYWOOD CUTTING OPTIMIZER FREE#

0 kommentar(er)

0 kommentar(er)